P20 STEEL PLATES Suppliers in Gurugram, India

Product description

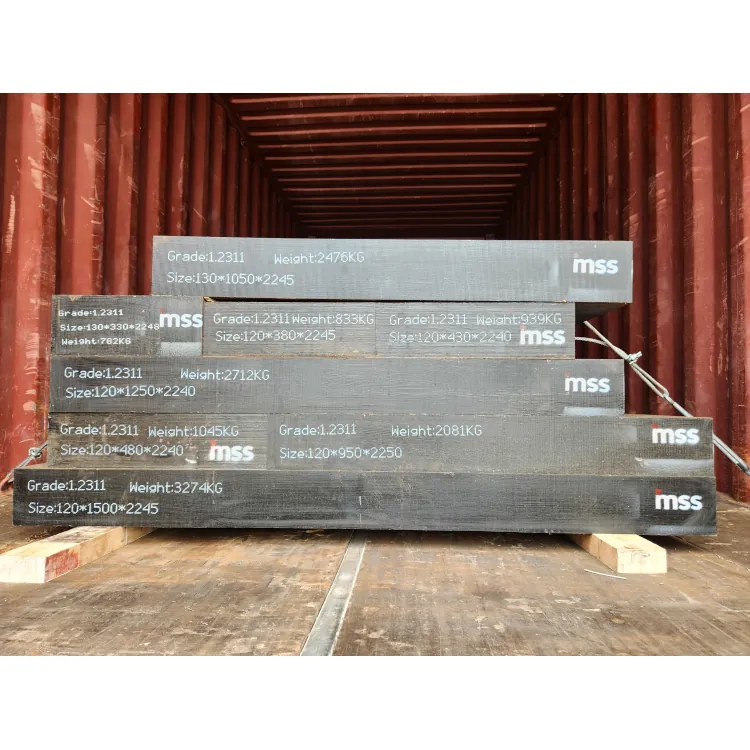

MILANO SPECIAL STEEL: Your Premier Partner for Premium P20 STEEL PLATES and Special Steel Grades in India

Over 50 Years of Excellence in P20 STEEL PLATES & Special Steel Supply

Since our establishment in 1972, MILANO SPECIAL STEEL has been a leading name in the Indian special steel market. With over five decades of unwavering commitment to quality and customer satisfaction, we have built a reputation as a trusted importer, supplier, and stockist of a diverse range of premium steel grades. Our extensive experience, coupled with a deep understanding of industry needs, allows us to provide exceptional products and services to clients across various sectors.

At MILANO SPECIAL STEEL, we understand that the success of your projects hinges on the quality of your materials. That’s why we specialize in offering top-tier steel solutions, ensuring that you receive materials that meet the most stringent international standards. Whether you require P20 STEEL PLATES, DIN 1.2311 plastic mould steel, or other specialized alloys, we are your reliable source for high-performance materials in both plate and round bar forms.

We proudly serve customers across all of India, with a strong presence and strategic locations in key industrial hubs including Gurugram, Kundli, Sonipat, Manesar, Bawal, Bhiwadi, Dharuhera, Faridabad, Haryana, Ghaziabad, Noida, Uttar Pradesh, Maharashtra, Bihar, West Bengal, Punjab, Gujarat, Bangalore, Pune, and Surat.

P20 STEEL PLATES: The Foundation of Precision in Plastic Moulding

What is P20 STEEL PLATES?

P20 steel is a versatile and widely recognized medium carbon, low alloy steel that is pre-hardened and renowned for its excellent machinability, good polishability, and superior dimensional stability. It is specifically designed to meet the rigorous demands of the plastic moulding industry, offering a perfect balance of hardness, toughness, and wear resistance. Its pre-hardened condition (typically between 28-32 HRC or 30-34 HRC) eliminates the need for further heat treatment after machining, significantly saving time and cost in mold production.

Key Properties of P20 STEEL PLATES

Understanding the properties of P20 steel is crucial for its effective application. Here are some of its core characteristics:

- Pre-Hardened State: P20 steel is supplied in a pre-hardened condition, eliminating the need for further hardening processes by the user. This feature simplifies manufacturing and reduces lead times.

- Good Machinability: Despite its hardness, P20 steel exhibits good machinability, allowing for intricate mold designs and precise finishing.

- Excellent Polishability: The fine microstructure of P20 steel enables it to achieve a high degree of polish, which is essential for producing high-quality plastic parts with smooth surfaces.

- Superior Dimensional Stability: P20 steel demonstrates excellent resistance to distortion during machining and service, ensuring the accuracy and longevity of molds.

- Good Toughness: It possesses sufficient toughness to withstand the stresses encountered during the injection moulding process, minimizing the risk of cracking or chipping.

- Moderate Wear Resistance: While not as wear-resistant as some tool steels, P20 steel offers adequate wear resistance for most plastic moulding applications, especially when combined with surface treatments.

- Consistent Hardness Uniformity: Our P20 steel offers consistent hardness throughout its cross-section, ensuring uniform performance of the mould.

- Nitridability: P20 steel can be nitrided to further enhance its surface hardness and wear resistance, extending the lifespan of moulds.

Need P20 Steel Plates or DIN 1.2311 Steel As India’s best suppliers, we offer premium quality, tailored sizes, and transparent price. Contact us!

P20 STEEL PLATES Applications

The exceptional properties of P20 steel make it an indispensable material in various industries, particularly those requiring high-quality plastic components. Its primary applications include:

- Plastic Injection Moulds: This is the most common application, covering a vast range of products from automotive components to consumer electronics and household goods.

- Die Casting Dies (Low Temperature): While primarily for plastic, P20 can be used for some low-temperature die casting applications.

- Mould Frames and Holders: Due to its dimensional stability and ease of machining, it’s also used for supporting structures in larger moulds.

- Rubber Moulds: Its properties are also suitable for the production of rubber components.

- Shear Holders: In certain applications, P20 steel can be used for shear holders where moderate hardness and good machinability are required.

DIN 1.2311 Steel: European Standard for Plastic Mould Steel

What is DIN 1.2311 Steel?

DIN 1.2311 steel is the European equivalent of P20 steel, specified under German industrial standards. It is a pre-hardened, chromium-molybdenum alloy steel specifically designed for plastic injection moulds and die casting dies. Like P20, it is supplied in a condition that typically does not require further heat treatment, making it a cost-effective and efficient choice for mould makers. Its consistent quality and performance are recognized globally.

Key Properties of DIN 1.2311 Steel

The properties of DIN 1.2311 mirror those of P20 steel, emphasizing its suitability for high-demand moulding applications:

- Pre-Hardened Delivery: Supplied typically in a hardness range of 280-320 HB (approx. 28-34 HRC), ready for machining.

- Excellent Machinability: Facilitates complex mould designs and reduces manufacturing time.

- Good Polishability: Allows for high-gloss surface finishes on moulded plastic parts.

- High Dimensional Stability: Resists deformation during heat cycling and machining, ensuring precise mould cavity dimensions.

- Good Toughness: Provides resistance to impact and shock during the moulding process.

- Uniform Hardness: Ensures consistent performance across the entire mould.

- Nitridable: Can be surface hardened through nitriding for improved wear resistance and extended mould life.

DIN 1.2311 Steel Applications

DIN 1.2311 is primarily used in the following areas:

- Large and Medium-Sized Plastic Injection Moulds: Ideal for components requiring a good surface finish and dimensional accuracy.

- Die Casting Dies for Low-Melting Point Alloys: Suitable for zinc, lead, and tin alloys.

- Compression Moulds: Used in the production of thermoset plastic parts.

- Mould Bases and Holders: Providing structural integrity for complex mould assemblies.

P20 Steel vs. DIN 1.2311 Steel: Understanding the Nuances

While P20 steel and DIN 1.2311 steel are often used interchangeably due to their similar properties and applications, there can be subtle differences based on manufacturing specifications and regional standards. Essentially, DIN 1.2311 is the European designation for a grade very similar to the American P20 standard. Both are premium pre-hardened plastic mould steels.

The primary difference lies in the specific compositional ranges and testing criteria defined by the respective standards (AISI for P20 and DIN for 1.2311). However, for practical purposes in the plastic moulding industry, they offer comparable performance characteristics. MILANO SPECIAL STEEL ensures that regardless of the designation, the steel we supply meets the highest quality benchmarks for its intended use.

Chemical Composition of P20 / DIN 1.2311 Steel (Typical)

Understanding the chemical composition is vital as it dictates the steel’s properties. Here’s a typical composition range for P20/DIN 1.2311 steel:

| Element | Percentage (%) |

| Carbon (C) | 0.28 – 0.40 |

| Silicon (Si) | 0.20 – 0.80 |

| Manganese (Mn) | 0.60 – 1.00 |

| Chromium (Cr) | 1.40 – 2.00 |

| Molybdenum (Mo) | 0.30 – 0.55 |

| Sulphur (S) | Max 0.030 |

| Phosphorus (P) | Max 0.030 |

The chemical compositions of DIN 1.2311, DIN 1.2312, DIN 1.2738, DIN 1.2085, DIN 1.2316S, DIN 1.2316, DIN 1.2083, and AISI 420S steels vary depending on their intended applications. For precise chemical compositions, consult the manufacturer's manual

The chemical compositions of DIN 1.2311 Steel, DIN 1.2312 Steel, DIN 1.2738 Steel, DIN 1.2085 Steel, DIN 1.2316S Steel, DIN 1.2316 Steel, DIN 1.2083 Steel, and AISI 420S steels are tailored to their specific applications, such as plastic molding, die casting, or corrosion-resistant tools. Each steel grade contains distinct percentages of elements like carbon, chromium, molybdenum, and others, influencing properties like hardness, toughness, and corrosion resistance. For example, DIN 1.2316 and AISI 420S often have higher chromium for enhanced corrosion resistance. For precise chemical compositions and detailed specifications, refer to the manufacturer's manual or technical data sheets.

Equivalent Grades and Alternative Grades

Knowing the equivalent and alternative grades is important for material selection and sourcing.

Equivalent Grades to P20 / DIN 1.2311 Steel:

- AISI P20: American Iron and Steel Institute designation.

- DIN 1.2311: German industrial standard.

- JIS SCM440 (modified): Japanese Industrial Standards, often a modified version for mould applications.

- GB 3Cr2Mo: Chinese National Standard.

- SS 2240 (modified): Swedish Standard.

Alternative Grades (for specific applications requiring different properties):

While P20/1.2311 is excellent, alternative grades may be considered for specific performance needs:

- P20+S: P20 with added sulfur for improved machinability, though it can slightly impact polishability.

- P20HH / 1.2312: A higher hardness version of P20, typically 36-40 HRC, for applications requiring greater wear resistance without additional heat treatment. MILANO SPECIAL STEEL also specializes in P20 high hard steel.

- 1.2738: Another widely used plastic mould steel, often with higher Nickel content, offering excellent through-hardening properties for larger mould dimensions.

- H13 (DIN 1.2344): A hot work tool steel, used for more demanding die casting applications or high-temperature plastic moulding where higher strength and heat resistance are paramount.

- 420 Stainless Steel (modified): For applications requiring corrosion resistance in addition to mould properties.

MILANO SPECIAL STEEL provides expertise in guiding you through the selection process, ensuring you choose the most suitable steel grade for your specific project requirements.

Our Supply Capabilities: Wholesale, Retail, and Custom Cut Pieces

At MILANO SPECIAL STEEL, we pride ourselves on our flexible and comprehensive supply chain solutions. We cater to a diverse clientele, from large industrial corporations to small and medium-sized enterprises.

- Wholesale Supply: We are equipped to handle large volume orders, providing competitive pricing and efficient logistics for major industrial projects.

- Retail Supply: Our robust inventory allows us to fulfill smaller quantity requirements, ensuring that even individual workshops or specialized fabricators have access to premium steel.

- Custom Cut Pieces: Understanding that every project has unique dimensions, we offer the convenience of supplying cut pieces sizes as per customer requirements. This service minimizes material waste and reduces machining time for our clients, saving both cost and effort.

Our commitment to timely delivery and precise cutting ensures that your production schedule remains uninterrupted.

Serving India’s Leading Industries

Our extensive experience and high-quality steel grades make us the preferred partner for a wide array of industries across India. Our major clients include:

- Aluminum Die Casting Industry: Providing robust steel for durable die casting moulds.

- Pressure Die Casting Industry: Supplying materials capable of withstanding high pressures and temperatures.

- Plastic Moulds Making Industry: Our core expertise, offering P20 and DIN 1.2311 for high-precision plastic injection moulds.

- Automotive Industry: Supplying steel for critical components, dies, and moulds used in vehicle manufacturing.

- Sheet Metal Cutting Industry: Providing wear-resistant steels for cutting tools and dies.

- Cutting Tools Making: Offering high-quality raw materials for the production of various cutting tools.

- Forging Industry: Supplying durable steels for forging dies and tools.

- Industrial Machines Manufacturing: Providing specialized steels for machine parts requiring strength and precision.

- Industrial and Defense Industry Parts Making: Delivering high-performance materials for critical and demanding applications.

Strategically Located Across India for Unmatched Service

Our strategic presence across major industrial hubs ensures prompt delivery and localized support for our clients. Our primary operational and supply regions include:

- Haryana: Gurugram, Kundli, Sonipat, Manesar, Bawal, Bhiwadi, Dharuhera, Faridabad

- Uttar Pradesh: Ghaziabad, Noida

- Maharashtra: Pune, Mumbai (surrounding areas)

- Bihar

- West Bengal

- Punjab

- Gujarat: Surat

- Karnataka: Bangalore

- Across ALL INDIA: Our robust logistics network enables us to serve any location within India, ensuring seamless delivery of your steel requirements.

Why Choose MILANO SPECIAL STEEL?

Choosing the right steel supplier is crucial for the success of your operations. Here’s why MILANO SPECIAL STEEL stands out as your ideal partner:

- Five Decades of Expertise: With over 50 years in the industry, we possess unparalleled knowledge and experience in special steel grades.

- Premium Quality Assurance: We strictly adhere to international quality standards, ensuring that every piece of steel we supply is of excellent quality and performance.

- Comprehensive Product Range: From P20 steel to DIN 1.2311 and other specialized grades, we offer a wide selection to meet diverse industrial needs.

- Customized Solutions: Our ability to provide custom cut pieces and flexible supply options (wholesale/retail) caters to unique project requirements.

- Competitive Pricing: We offer high-quality steel at competitive market prices, ensuring excellent value for your investment.

- Nationwide Reach: Our extensive distribution network ensures timely delivery across India.

- Customer-Centric Approach: We prioritize understanding and fulfilling our clients’ specific needs, offering expert guidance and support.

- Reliability and Trust: Our long-standing reputation is built on reliability, transparency, and building lasting relationships with our clients.

Contact MILANO SPECIAL STEEL Today!

Ready to experience the MILANO SPECIAL STEEL difference? Whether you need premium P20 steel, DIN 1.2311, or other specialized steel grades, our team of experts is ready to assist you.

Visit our websites to learn more about our products and services:

- https://p20steelsupplier.com/

- https://www.milanospecialsteel.com/

- https://www.p20highhardsteel.com

- https://www.p20steel.com

For inquiries, quotations, or expert advice, feel free to contact us: Email: [email protected]

Let MILANO SPECIAL STEEL be your trusted partner for all your special steel requirements. We look forward to building a successful and long-term relationship with you.