XPM ESR Material, XPM Material a High-Hard Plastic Mould Steel 39-44 HRC

Product description

XPM ESR Material: The Ultimate High-Hard Plastic Mould Steel (39-44 HRC) | Milano Special Steel

In the competitive landscape of modern plastic molding, the quality, longevity, and performance of the mould are paramount. For complex, high-volume, and high-precision applications, standard mould steels often fall short.

This is where XPM material emerges as a superior solution—a high-performance, pre-hardened tool steel engineered for the most demanding moulding challenges. Supplied in a ready-to-use hardness of 39 HRC to 44 HRC, this steel eliminates the need for post-machining heat treatment, revolutionizing the mould-making process.

As India’s foremost XPM ESR material supplier, Milano Special Steel provides this exceptional grade to manufacturers seeking unparalleled performance.

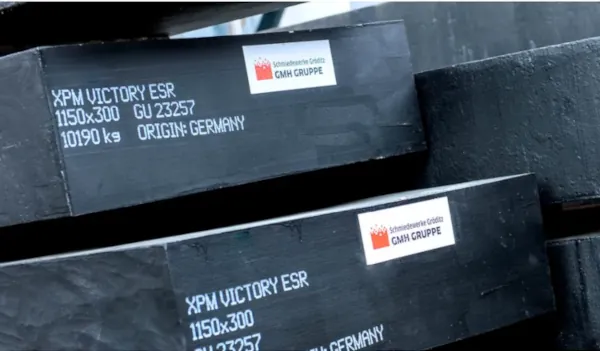

We specialize in supplying premium XPM ESR material in high-hard plastic mould steel forged blocks, offering a unique combination of extreme wear resistance, excellent polishability, and superior toughness. With a legacy spanning over five decades, we are the trusted partner for industries that refuse to compromise on quality.

This definitive guide explores the properties and advantages of XPM material, its critical applications, and why Milano Special Steel is your ideal source for this advanced tool steel in India.

What is XPM Material? Decoding the High-Performance Advantage

XPM material is a specialized grade of tool steel, developed explicitly for high-end plastic mould applications. Its defining characteristic is that it is delivered in a pre-hardened condition, typically ranging from 39 HRC to 44 HRC. This high hardness level provides exceptional wear resistance and compressive strength, making it ideal for long production runs and for moulding abrasive or fibre-reinforced plastics.

The “ESR” in XPM ESR material stands for Electro-Slag Remelting. This is a secondary steel refining process that takes standard, high-quality steel and purifies it to a much higher degree. The ESR process removes non-metallic inclusions, dissolved gases, and other impurities, resulting in a steel that is:

-

Exceptionally Clean and Homogeneous: A uniform microstructure ensures consistent properties throughout the entire block.

-

Superiorly Tough: The absence of impurities minimizes internal stress points, significantly enhancing toughness and resistance to cracking.

-

Highly Polishable: The ultra-clean nature of ESR steel allows for a flawless, mirror-like polish, which is essential for producing high-gloss plastic parts.

-

Excellent Fatigue Resistance: The refined structure improves the material’s ability to withstand the cyclical stresses of mould opening and closing.

By combining a high pre-hardened state with the purity of the ESR process, XPM ESR material offers a performance profile that is unmatched by conventional mould steels like P20 or 1.2312. It is the definitive choice for mould makers who need to deliver top-tier moulds with shorter lead times and greater reliability.

The Power of Pre-Hardened Steel: 39 HRC to 44 HRC

The single most significant advantage of XPM material is that it eliminates the heat treatment step from the mould maker’s workflow. Traditionally, moulds are machined from annealed (soft) steel and then sent out for a complex hardening and tempering process. This process is not only time-consuming and costly but also fraught with risks:

-

Distortion and Warping: The intense heating and cooling can cause the precisely machined mould to change shape.

-

Cracking: Thermal stress can lead to catastrophic cracks, scraping the entire mould.

-

Size Variation: Unpredictable dimensional changes can ruin tight tolerances.

-

Inconsistent Hardness: Achieving uniform hardness, especially in large blocks, is challenging.

XPM material, supplied by Milano Special Steel at a ready-to-use hardness of 39-44 HRC, completely bypasses these issues. You can machine directly into the hardened block, saving weeks of production time, eliminating heat treatment costs, and eradicating the associated risks.

Buy XPM ESR Material, XPM Material, a High-Hard Plastic Mould Steel 39-44 HRC in India.

Chemical Composition: Engineered for Excellence

The specific chemical composition of XPM material is a carefully balanced, often proprietary formula designed to achieve its unique blend of high hardness, toughness, and machinability. As a premier XPM ESR material supplier, Milano Special Steel guarantees a grade with an optimized alloying content.

While the exact percentages are a trade secret, the key elements and their contributions are well-understood:

| Element Probable | e Contribution in XPM Material |

|---|---|

| Carbon (C) | A moderate to high carbon content provides the high base hardness (39-44 HRC) and wear resistance. |

| Chromium (Cr) | Essential for deep hardenability, ensuring the hardness is uniform even in very large forged blocks. Also improves polishability and corrosion resistance. |

| Molybdenum (Mo) | Enhances toughness at high hardness levels, improves through-hardening, and increases temper resistance. |

| Nickel (Ni) | Often added to pre-hardened steels to significantly boost toughness and ensure uniform hardening. |

| Vanadium (V) | Promotes a fine-grain structure, which enhances wear resistance and ensures the steel can be polished to a high degree. |

| Manganese (Mn) & Silicon (Si) | Contribute to the steel’s strength, hardenability, and refining during the manufacturing process. |

This sophisticated metallurgy results in a steel that, despite its high hardness, exhibits surprisingly good machinability, allowing for efficient production of complex mould cavities.

Milano Special Steel: Your Trusted Supplier of XPM ESR Material in India

Choosing a supplier for a high-performance material like XPM is a critical decision. With a history dating back to 1972, Milano Special Steel offers more than 50 years of experience in the special steels industry. Our reputation is built on a commitment to quality, innovation, and unwavering customer satisfaction.

Why Partner with Milano Special Steel?

-

Specialists in High-Performance Steels: We are not just general steel traders. We are specialists. We understand the unique demands of high-hardened plastic mould steel and have curated our inventory to include premium grades like XPM ESR material.

-

Guaranteed Quality and Hardness: We supply genuine XPM ESR material as forged blocks with a certified hardness of 39 HRC to 44 HRC. The ESR process ensures the highest level of purity, and our rigorous quality control guarantees you receive material that performs as promised.

-

Best Price Advantage: As a leading importer, manufacturer, and large-volume stockist, we leverage our economies of scale to offer the most competitive prices in the Indian market. We provide premium material without the premium price tag.

-

Extensive Inventory and Custom Sizing: We maintain a substantial inventory of XPM material in a variety of forged block sizes. More importantly, we offer precision cutting services to supply custom-sized pieces based on your specific mould dimensions. This minimizes your material waste and initial machining time.

-

Unmatched Distribution Network: Our strategic operational hubs in Gurugram, Kundli, Sonipat, Manesar, Bawal, Bhiwadi, and Dharuhera are perfectly positioned to serve the industrial heartlands of India. This network ensures fast, reliable delivery to every corner of the country.

From Pune’s automotive cluster to Bangalore’s tech manufacturing, and from Surat’s industrial zones to the national capital region, Milano Special Steel is your local supplier with a national footprint.

Applications: Where XPM ESR Material Delivers Maximum Value

The unique properties of XPM ESR material make it the ideal choice for a wide range of demanding tooling applications, particularly in the plastic injection moulding industry.

High-End Plastic Injection Moulds

This is the primary application for XPM steel. It excels in:

-

Moulds for Automotive Components: Perfect for large, complex moulds used for bumpers, dashboards, door panels, and lighting fixtures, where high surface quality and dimensional stability are critical.

-

Moulds for Consumer Electronics: The exceptional polishability of XPM ESR material is essential for creating the glossy, flawless casings of smartphones, laptops, and other electronic devices.

-

Molds for Home Appliances: Used for producing durable and aesthetically pleasing parts for washing machines, refrigerators, and kitchen appliances.

-

Moulds Using Abrasive Plastics: The high hardness (39-44 HRC) provides excellent resistance to the wear caused by glass-filled or mineral-filled polymers, dramatically increasing mould life.

Large Mould Bases and Holders

The excellent through-hardenability of XPM makes it a superior choice for large mould bases and bolster plates. Its high compressive strength prevents indentation and deformation under high clamping pressures.

Compression Moulds

In compression moulding, the steel must withstand high pressure and temperature over long cycles. XPM’s combination of hardness and toughness ensures it resists wear and deformation, leading to a longer operational life.

High-Stress Structural Components

Beyond moulding, the material’s properties make it suitable for other high-stress industrial applications, such as machine parts, jigs, and fixtures that require high strength and wear resistance without the need for additional heat treatment.

Pressure Die Casting Applications

While primarily a plastic mould steel, the inherent toughness and hardness of XPM make it suitable for specific components in die casting, such as holder blocks, support pillars, and other ancillary tooling that require high strength and stability.

Serving Industries Across the Length and Breadth of India

As India’s premier XPM ESR material supplier, our mission is to empower manufacturers nationwide. Our logistics network is designed for efficiency and reach.

Our Core Service Hubs:

-

Gurugram

-

Kundli

-

Sonipat

-

Manesar

-

Bawal

-

Bhiwadi

-

Dharuhera

Nationwide Delivery to Every State and UT:

We proudly serve clients in every state: Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Goa, Gujarat, Haryana, Himachal Pradesh, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, and West Bengal.

Our reach also extends to all Union Territories: Andaman and Nicobar Islands, Chandigarh, Dadra and Nagar Haveli and Daman and Diu, Delhi (NCT), Jammu and Kashmir, Ladakh, Lakshadweep, and Puducherry.

Wherever your facility is located, Milano Special Steel is your reliable partner for on-time delivery of high-quality tool steels.

Frequently Asked Questions (FAQ) about XPM ESR Material

As experts in high-hardened plastic mould steel, we often address key questions from our clients.

Q1: How does XPM material compare to P20 or P20+Ni steel?

XPM is a significant upgrade from P20-grade steels. While P20 is typically supplied at around 28-32 HRC, XPM material is provided at 39-44 HRC. This higher hardness translates to substantially better wear resistance and compressive strength, making it suitable for much longer production runs and more abrasive materials. The ESR manufacturing process also gives it superior polishability and toughness compared to standard P20.

Q2: Is XPM ESR material difficult to machine because of its high hardness?

While it is harder than conventional steels, XPM material is specifically engineered for good machinability at its supplied hardness. Modern cutting tools and machining strategies can be used to efficiently cut, mill, and drill XPM. The time saved by skipping heat treatment far outweighs any marginal increase in machining time.

Q3: What does “ESR” guarantee for my mould?

ESR (Electro-Slag Remelting) guarantees steel with ultra-low impurities. For your mould, this means two critical things:

-

Superior Polishability: You can achieve a flawless, mirror-like surface finish, essential for high-quality optical and cosmetic parts.

-

Enhanced Toughness: The material is far less likely to crack during heavy machining or under the high stresses of operation, protecting your significant investment in the mould.

Q4: Can Milano Special Steel provide a material test certificate for XPM material?

Absolutely. Every batch of XPM ESR material we supply comes with a comprehensive material test certificate (MTC). This certificate verifies the chemical composition, hardness, and other key properties, giving you complete confidence in the quality of your purchase.

Q5: Do you supply XPM in forged blocks? What is the advantage?

Yes, we specialize in supplying XPM material in forged blocks. Forging refines the grain structure of the steel, improving its mechanical properties, especially toughness and impact strength, compared to simple cast or rolled material. It ensures a dense and robust block ready for demanding applications.

Q6: I need a specific block size for my mould. Can you provide it?

Yes. We understand that minimizing waste is crucial. We offer custom cutting services to provide you with a forged block cut to your precise length, width, and thickness requirements. This saves you time, money, and machining effort.

Conclusion: Partner with the Best XPM ESR Material Supplier in India

In a market that demands speed, precision, and durability, your choice of mould material is a defining factor for success. XPM ESR material offers a revolutionary advantage, providing a high-hardness (39-44 HRC), ultra-clean, and ready-to-use solution that streamlines mould production and enhances final product quality.

By choosing Milano Special Steel as your XPM ESR material supplier, you are investing in more than just steel. You are gaining a partner with over half a century of expertise, a steadfast commitment to quality, the most competitive pricing, and a logistical network built to serve you anywhere in India. We provide high-hardened plastic mould steel forged blocks that form the foundation of manufacturing excellence.

Contact Us Today

Elevate your tooling capabilities with premium XPM material. Contact us for the best price and expert consultation.

Visit our websites for more details:

For inquiries, technical questions, and to request a quote, email us at:

[email protected]

Trust Milano Special Steel to be the backbone of your most demanding projects.