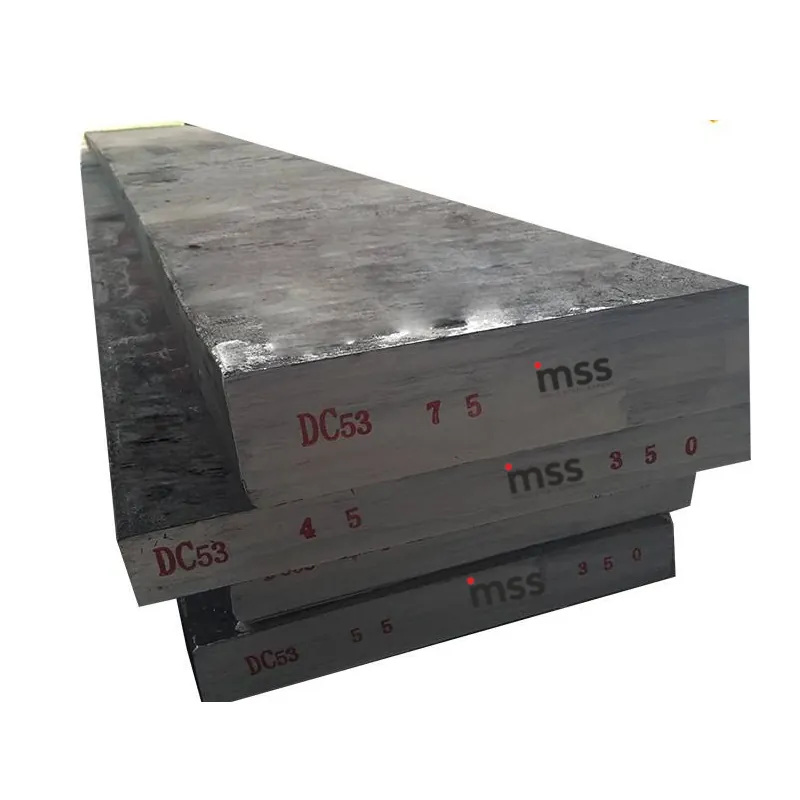

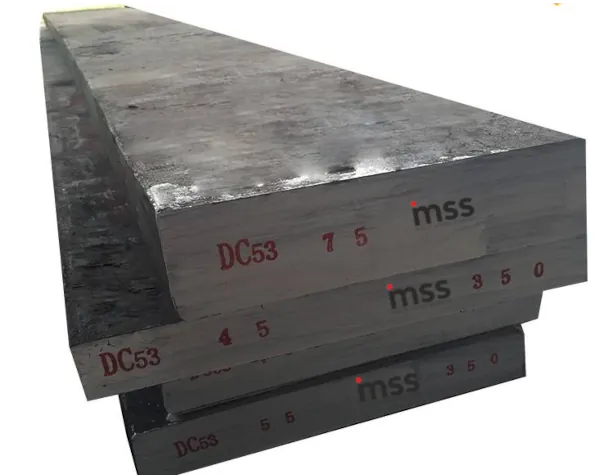

DC53 Steel, Price, Suppliers in Delhi NCR, India, Manufacturers

Product description

DC53 Steel, Price, Suppliers in Delhi NCR, India, Manufacturers & Overview

Introduction about DC53 steel

DC53 steel is an advanced cold work die and mold steel recognized for its exceptional combination of strength and toughness—properties that nearly match those found in high-speed steels.

Developed as an upgrade from the conventional D2 tool steel as specified by JIS G4404, DC53 addresses the drawbacks of D2, particularly its reduced hardness and toughness following high-temperature tempering.

By overcoming these limitations, DC53 Steel is positioned as a strong replacement for D2 in both general-purpose and high-precision die applications.

In addition to its robustness, DC53 Steel exhibits excellent machinability, making it an ideal substrate for PVD surface treatments.

It also supports hot process CVD and TD (Thermal Diffusion) coatings, though a post-heat treatment is generally recommended for optimal performance.

Available Services

-

Hardening and tempering

-

Vacuum heat treatment

-

Polished bright surfaces

-

Milled bright surfaces

-

CNC machining

-

Deep drilling

-

Cutting to smaller pieces or precise mold sizes

-

Custom precision cutting and finishing to client specifications

Surface Grinding/Polishing Capabilities

-

Thickness tolerance: -0 to +0.1mm

-

Flatness: 0.01/100mm

-

Surface roughness: Ra ≤1.6 or Rz ≤6.3

Key Advantages of DC53 Steel

-

Achieves higher post-heat treatment hardness (62–64 HRc) than D2.

-

Delivers double the toughness and superior wear resistance compared to D2.

-

Possesses significantly greater fatigue strength.

-

Features smaller primary carbides, which minimize chipping and cracking.

-

Enhanced by secondary refining processes (DLF) to reduce impurities.

-

Machines and grinds up to 40% faster than D2.

-

Demonstrates reduced residual stress after wire EDM processing.

DC53 Steel Typical Applications

-

Stepped punches and press-punching dies

-

Parts for concrete sprayers, rotor plates

-

Swaging dies, backers

-

Cold forging dies

-

Thread-rolling dies (including for heat-treated bolts)

-

Forming and piercing punches

-

Stripper plates for lead frame blanking

-

Gauges and screws for injection molding machines

-

Plastic molds

These versatile uses are supported by DC53’s unique chemical composition and advanced manufacturing methods, including ladle refinement, vacuum degassing, and specific forging techniques. The steel’s excellent machinability and suitability for surface treatments, such as PVD, CVD, and TD coatings, make it highly adaptable for modern tooling needs.

DC53 Steel, Best Price, Suppliers in Gurugram, Punjab, Delhi NCR, India, Manufacturers

DC 53 Steel Standards and Composition

-

Industry Standard: Complies with ASTM A681 – 08 Standard Specification for Tool Steels Alloy.

-

Typical Chemical Composition of DC53 Steel (%):

C Si Mn Cr Mo V 0.95 1.0 0.40 8.0 2.0 0.30

DC 53 Steel Heat Treatment Guidelines

Hardening

-

Typically air-hardened in a vacuum furnace, it can also be processed using gas or electric furnaces or by salt bath hardening.

-

Lower minimum pre- and post-heating temperatures than D2 reduce weld cracking risks.

-

Process:

-

Preheat: 300–400°C, then 800–850°C.

-

Austenitize at 1,020–1,040°C and soak for a sufficient period.

-

Quenching: A Vacuum furnace is recommended due to high hardenability.

-

Air Hardening

-

Preheat and hold at 800–850°C, then austenitize at 1,030°C.

-

Quench using inert gas at 2 bar pressure.

-

Immediate tempering is necessary after quenching.

Salt Bath Hardening

-

Preheat to 850°C, austenitize in molten salt at 1,030°C, and then quench in salt. Allow to cool to 45–65°C before tempering.

Tempering

-

Double temper based on desired hardness and toughness.

-

For high hardness (HRC 62–64): Temper twice at 520°C.

-

For high toughness: Temper twice between 200–300°C.

-

A third temper at 400°C can improve dimensional stability for high-precision uses.

Additional Treatments

-

Vacuum tempering and cryogenics (optional, for increased toughness).

-

Forging range: 900–1,100°C; annealing is recommended post-forging.

Inspection and Quality Control

-

Hardness testing and precise dimensional measurements are essential after heat treatment.

-

Typical growth on proper heat treatment is 0.1%–0.15% of the original size.

Surface Treatments

DC53 Steel is compatible with a wide range of surface treatments, including:

-

Nitriding (case hardening)

-

PVD (Physical Vapor Deposition)

-

CVD (Chemical Vapor Deposition)

-

TD (Thermal Diffusion/Reactive Diffusion)

These treatments are either integrated into the substrate (case hardening) or applied as a thin surface coating. Combined treatments may increase surface hardness, as detected by microhardness tests, but not always by traditional hardness methods.

Sample Application: Blanking Dies

A comparison in cold pressing Ni-based alloy showed DC53 Steel (tempered at 520°C and achieving HRc62/63) outperformed D2 (tempered at 510°C, HRc58/59), with 25,000S versus 5,000S durability in testing—demonstrating approximately five times the lifespan under typical tooling conditions.

Certification

All products are provided with EN 10204/3.1 mill certificates, which include the full chemical composition, mechanical properties, and test results.